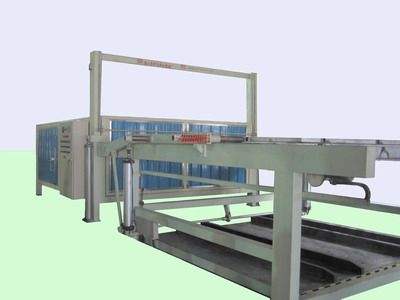

Nowadays, the forming building of ceramic production enterprises, high-pressure forming grouting building, is composed of multiple sets of moulds, which is not suitable for various and small-batch production forms; the moulds are grouted by suspension method, and the moving of the mould base plate needs to move back and forth, the positioning accuracy is poor, the operation intensity is high, and it is difficult to end the demoulding automation; the clamping method is constrained, and the standard of the base plate should not be too large, not too large. The production of basin is standardized and satisfactory; the clamping and clamping are finished by the same cylinder, the hydraulic pipeline system and control system are complicated, the power consumption is large, and the clamping speed is slow, which leads to high planning cost, low power of system integration and complex operation and maintenance. The side-effect force of locking is supported by the layout of the building, which leads to the large selection standard of building materials, the high intensity of building production/construction operation, and the waste of manpower, material and financial resources. A single-station automatic forming machine includes main frame, robot, open-close placement, substrate A and B for locking construction, clamping cylinder for supplying locking force, hydraulic building for supplying pressure for clamping cylinder, control building and pressure sensor. Its characteristics include: torsion placement of building on base plate B, sleeve at the end of torsion placement building. The torsion shaft placed in torsion is connected with the inner wall of the sleeve through bearings, and the sleeve is fixed on the base plate B. The end of the torsion shaft placed in torsion has an oval opening for locking. The touching part of the torsion shaft and the base plate B is provided with an axle shoulder to reduce the radial load of the torsion placement and the torsion shaft. The end of the clamping cylinder is constructed with a fixed sleeve, and the fixed sleeve is fixed with the base plate A. The fixed sleeve is connected with external threads at one end far from the base plate A, and the torsion sleeve is connected with the fixed sleeve through internal and external threads. The cylinder pull rod of the clamping cylinder passes through the fixed sleeve and the torsion sleeve and is provided with a locking head at the end. The locking head is oval and matches the oval female mouth. After the oval male mouth and the female mouth are connected, the torsion is placed to rotate 90 degrees. The locking head is in a locking environment; the phase side of the substrate A and B is respectively provided with a mould A and B, and the bottom of the main frame is provided with an opening and closing position for the opening and closing of the mould; after the locking head is locked, the hydraulic building of the automatic forming machine starts, the clamping cylinder drives the cylinder pull rod to retract, and the pressure sensor detects the pressure and transmits the signal to the control building to end the pressure. Size control.